Introduction to Design for Manufacturing (DFM)

Design for Manufacturing (DFM) is a critical approach in product development, focusing on designing products for ease of manufacturing. Our process optimizes design to ensure cost-effective and efficient production. By incorporating DFM, products are not only innovative but also practical to produce on a large scale. We reduce production costs, streamline the manufacturing process, and shorten the time-to-market.

DFM is essential for creating high-quality products while maintaining profitability, preventing costly redesigns and ensuring a smoother transition from concept to mass production.

Our DFM service in detail

Review Initial Design

In this initial phase, we meticulously review the product design submitted by you. Our team assesses every aspect, from aesthetics to functionality, ensuring it aligns with both your vision and manufacturing feasibility.

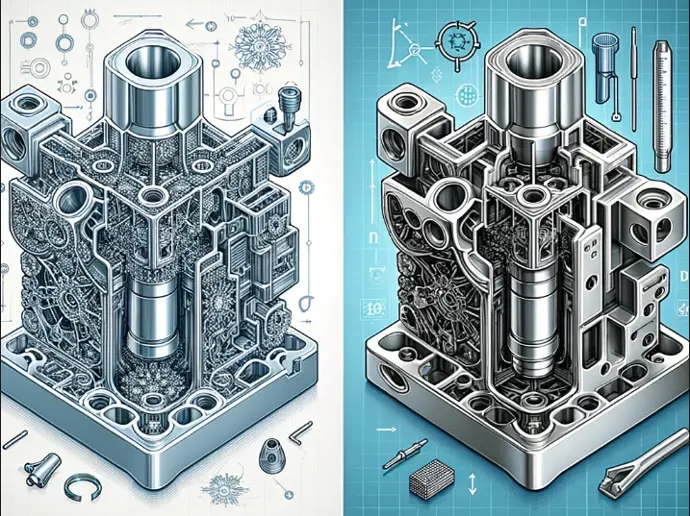

Simplify design

We focus on refining and simplifying your product design. This involves reducing complexity, optimizing part design for moldability, and ensuring the design is both cost-effective and suitable for high-quality production. Our goal is to make your design injection-mold friendly while maintaining its core functionality and aesthetic appeal.

Cost of goods reduction

We concentrate on optimizing your Bill of Materials (BOM) to reduce costs without compromising quality. Through careful analysis and strategic sourcing, we identify areas for cost savings, from material selection to component consolidation. Our goal is to ensure your product is economically viable for production, balancing cost-effectiveness with high manufacturing standards.

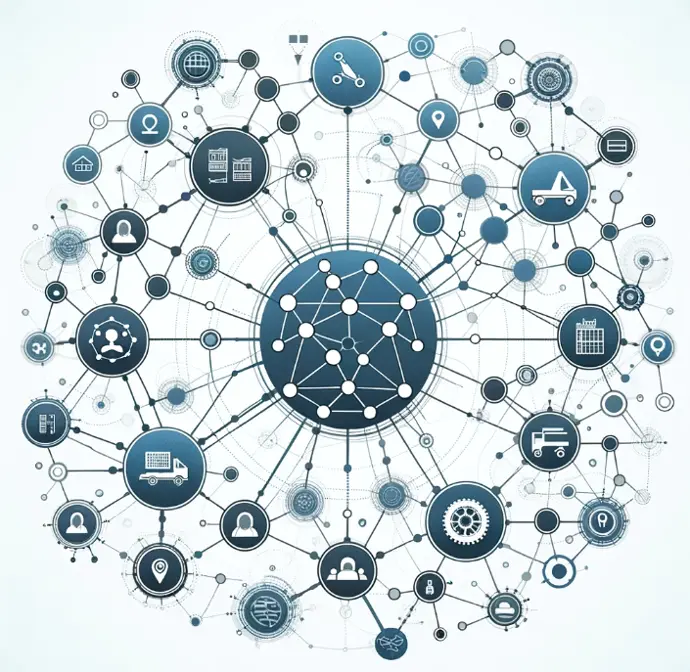

Supply Chain Integration

We focus on integrating your product into a cohesive supply chain system. We align various elements – from material suppliers to manufacturers and distributors – ensuring a seamless flow from production to delivery. Our aim is to create an efficient, reliable supply chain that supports your product's manufacturing cycle, enhancing overall efficiency and reducing time-to-market.

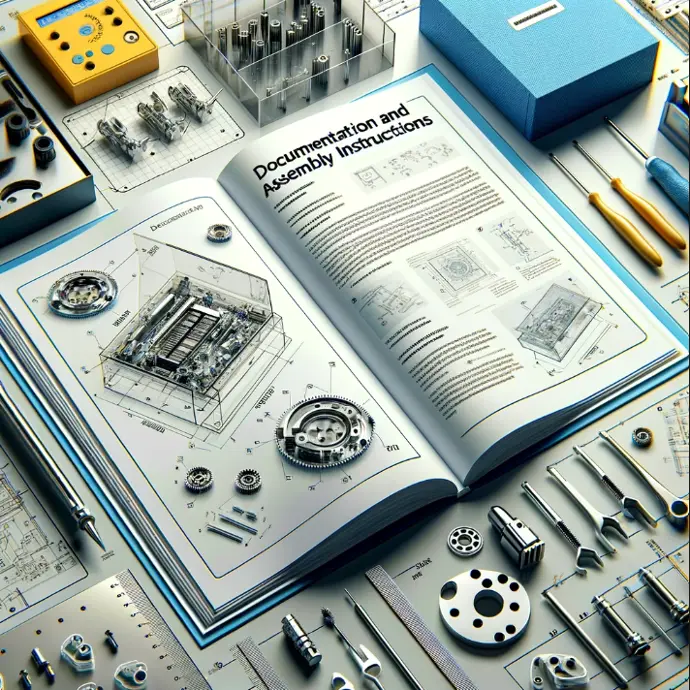

Assembly Instructions

We create detailed documentation and assembly instructions for your product. This includes clear, step-by-step guides and diagrams, ensuring that the manufacturing process is straightforward and efficient. Our focus is on precision and ease of understanding, enabling smooth assembly and quality assurance in production. This documentation serves as an essential resource for your manufacturing team, facilitating a hassle-free assembly process.

Begin Mass Production

Reaching the final stage of our DFM process, we begin mass production of your product. The transition to mass production is seamless, thanks to our meticulous planning and optimization in the earlier stages. We ensure that every unit produced meets the highest standards of quality and consistency, fulfilling your vision in its most tangible form.

Bring Your Idea to Life: Tap into expert Design for Manufacturing services.

Awesome brands that we successful worked for